Description

x

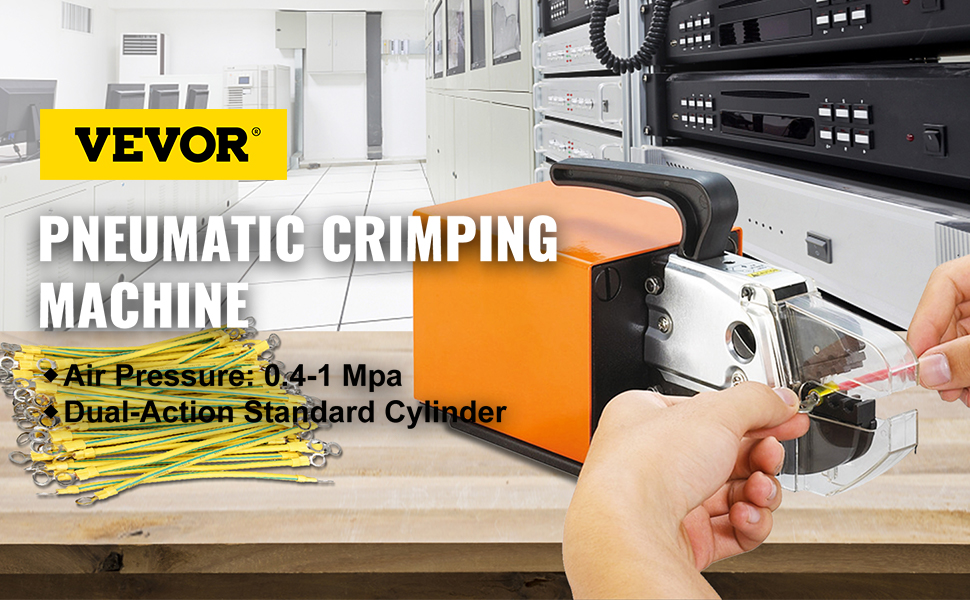

1.3 T Pneumatic Crimping Machine

A pneumatic crimping machine is driven by a dual-action standard cylinder, which has advantages of high efficiency and quality in crimping force and speed. It is suitable for Non-insulated terminals ≤ 16 mm2, Rre-insulated terminals ≤ 6 mm2, Tube terminals ≤ 35 mm2. The die sets can be interchangeable with our manual crimping tools

-

Durable Material -

High Efficient -

Comfortable Operation -

Easy to Use

Dual-acting Cylinder

Compared with single-acting cylinders, double-acting cylinders are more economical, have fast crimping speed, wide application range, and long service life.

Solid Steel Material

Tool steel material, surface painting process, having superior mechanical properties. High hardness, wear resistance, long time operation.

High-precision Jaw

The crimping machine has high-precision jaws, crimping accurately, and will not damage the terminals. You can also replace the jaws to press out different terminals.

Labor-saving Design

Foot-operated air valve design makes crimping effortless. The air valve can also control the crimping pressure and accurately crimp the terminals.

Simple Operation

The clamps are used in pairs, follow the instructions to connect the crimping machine correctly, which is easy to use.

Widely Use

Pneumatic crimping machine for a variety of terminal press-bonding, the die can be pressed with our manual crimping tool used interchangeably.

Specifications

-

Model: AM-10 -

Material: Tool steel -

Weight: 3.5 kg (7.7 lbs) -

Output Force: 1.3 T -

Air Pressure: 0.5-0.7 Mpa -

Max. Operating Pressure: 1.0 Mpa -

Non-insulated terminals ≤ 16 mm2 -

Rre-insulated terminals ≤ 6 mm2 -

Tube terminals ≤ 35 mm2 -

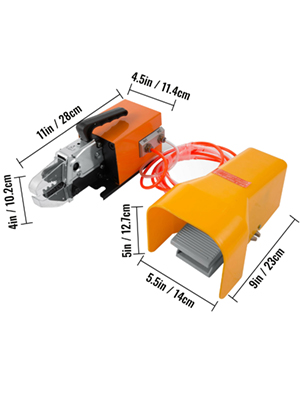

External Dimension: 266 x 142 x 117 mm ( 9 x 5.6 x 4.6 inch)

Package Content

-

1 x AM-10 Pneumatic Crimping Machine -

1 x Die Set -

1 x Foot Air Valve -

2 x Air Pipes

- Choosing a selection results in a full page refresh.